STEEL & FLUID CASE STUDY

Visibility is Key to Production Efficiency

The future of SC Steel & Fluid Co SRL (SFCo) has been transformed by a new management team, new processes, and technology. In just a few months, every key metric has dramatically improved:

- Customer satisfaction

- Quality

- Efficiency

- Profitability

LiveDataset was central to the technology strategy. In this case study, we will show how SFCo has rapidly implemented LiveDataset from the factory floor to the finance department, creating a vital layer of transparency and helping to transform its relationship with external stakeholders.

1 Manufacturing Steel Mechanical Products

SFCo manufacture steel mechanical products such as hydraulic cylinders, basements, large components and sub-assemblies. These are used by industrial customers, including manufacturers of cranes, food and beverage equipment.

Most products are designed and built to order. The manufacturing process encompasses:

- Technical design and documentation

- Sourcing materials

- Scheduling time on machines for each stage of the manufacturing process

- Finishing (sand-blasting, painting)

- Quality assurance

- Transport to customer

At each stage, the different teams need to know about upcoming work, so they can plan ahead and prioritize their work.

2 Traditional ERP Lacked Flexibility

Previously, SFCo used a traditional ERP system for accounting and managing production. But the very specialized nature of their production process was not well suited to a traditional ERP.

Like a square peg in a round hole, the ERP was not flexible enough to cope with having so many jobs each following a different process. Using the system became more complex and confusing and visibility into the entire production process was lost between the different departments and the management.

The consequences were serious:

- Late orders

- Cost and waste increases, consequences of poor process control

- Reduced quality

- Unhappy customers

The financial viability of the entire company was at stake as manufacturing became less and less profitable.

3 A New Start

In late 2017, SFCo was acquired by new owners, who introduced a new management team and a new approach. Their vision was to dramatically increase efficiency by optimizing processes and bringing total visibility to every part of the manufacturing process from taking orders to delivery.

They considered implementing a new modern ERP system or reconfiguring their existing systems. Either way, the systems work would require extensive funding, people, and many months to complete. It would be too risky and too disruptive.

The existing systems worked for each team in their own silo. They had the detailed information they needed for their own work. What they needed was a way to join up the processes. So, everyone could work with one set of consistent information.

Rather than changing the current transactional systems, LiveDataset was added as a new layer above the existing systems. They built new processes in LiveDataset, so information flows seamlessly through the business to increase quality and efficiency.

The priority was to optimize three workflows where significant results could be realized in a few weeks:

- Cash management

- Order management

- Quality management

4 Cash Management

The first area for SFCo to tackle was managing cash flows. From an accounting perspective, all financial transactions were being accurately recorded. But that only told SFCo what had happened. To efficiently manage cash, they needed to accurately forecast day-by-day the cash position for the next eight weeks.

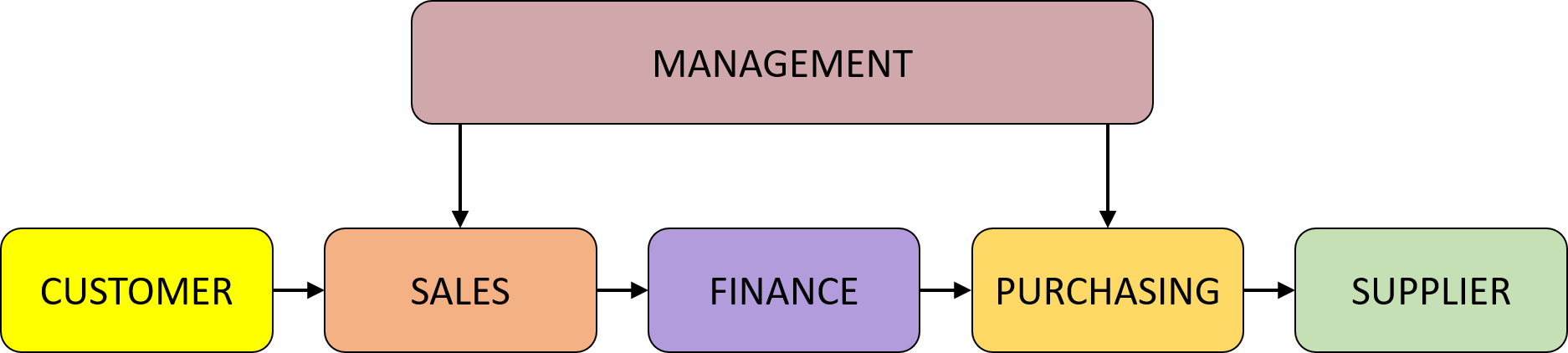

This meant different teams working together. Each team had different responsibilities but working together on the same set of data made it very easy for them all to see the latest information and keep it up-to-date.

| Sales team | Cash-in: Invoices due and expected payments collection. |

|---|---|

| Purchasing team | Cash-out: Purchase orders and commitments due. |

| Finance team | Cash-in and cash-out: E.g. loans and payroll. |

| Management team | Oversight and approvals for large payments. |

Results

Better visibility helped improve financial discipline and anticipate issues in advance. For instance:

- Supporting timely payment planning with clients and shining a spotlight on customers who were paying late.

- Early warning of cash flow problems on specific days over the next 8 weeks.

- Identifying when payment schedules need to be negotiated.

- Clear process for management to approve payments.

“We needed to quickly get careful control of cash. Now every day, top management can review cash requirements for the coming 8 weeks and authorize large payments.”

— SFCo CFO

5 Order Management

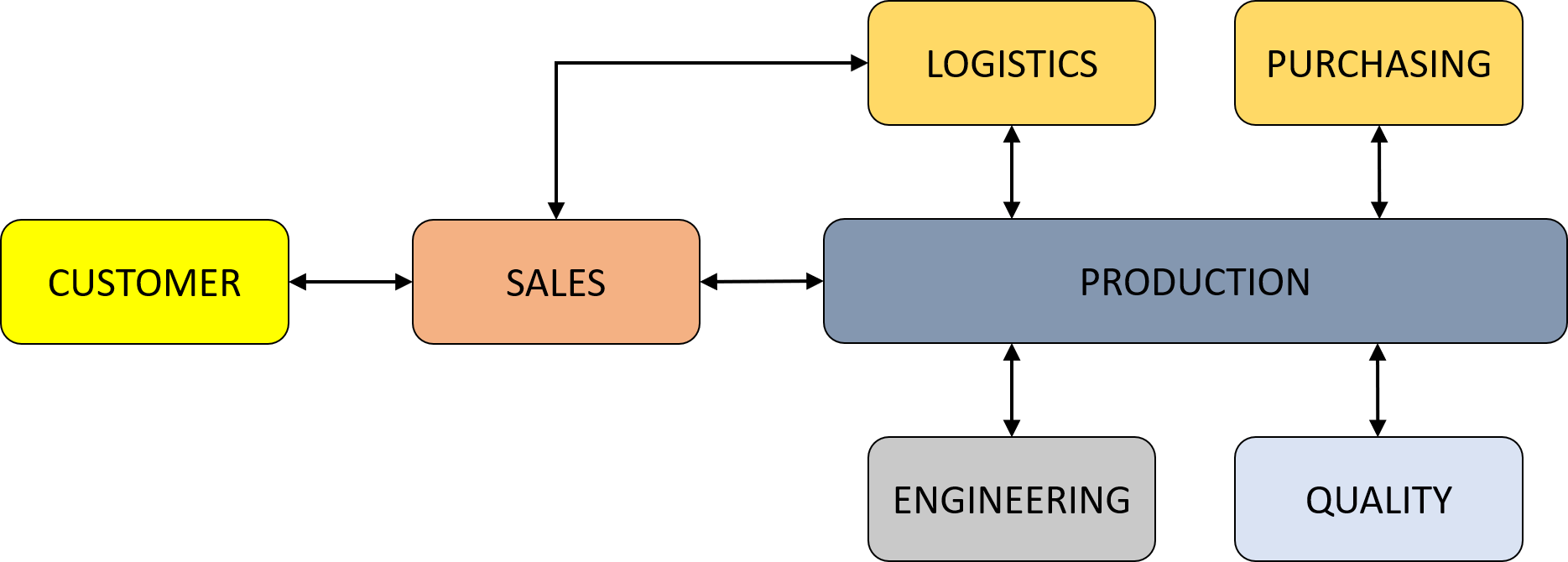

The most critical factor for streamlining the entire process from a customer ordering a product to receiving it – is timing. Everyone needs to be completely clear on when production will start and when the order will be delivered to the customer.

By carefully scheduling the various steps, each team knows when their contribution is needed, and most importantly the customer can plan their work knowing the delivery date is reliable. Of course, there will be occasional delays. But having a clear plan means changes can be incorporated in a managed way – with everyone being able to see the impact on their work.

| Sales team | Receive orders from customers with requested delivery date. Confirm delivery date to customers and notify customers of any delays. |

|---|---|

| Production team | Plan manufacturing phases for order and specify when production will start. |

| Engineering team | Provide technical documentation before production starts. |

| Purchasing team | Ensures necessary raw materials in warehouse before production starts. |

| Logistics team | Ensures suitable transport arranged for ship date. |

| Quality team | Ensures specialists assure quality before ship date. |

Results

Efficiency and predictability have dramatically increased. The teams are closely synchronized as they are all working on same data.

- Faster manufacturing

- Fewer delays

- Reduced waste

- Improved machine utilization

Customers appreciate the step change in reliability. Inevitably unexpected issues still arise, but now SFCo immediately see if the delivery date will be delayed. And customers can be told weeks in advance.

Some regular customers even have direct read-only access to the data on their orders, so they can monitor process throughout the manufacturing process, seeing dates for production start, completion, and delivery. This has helped improve the relationship with key customers. Giving them complete transparency is building trust, confidence, and a collaborative partnership throughout the supply chain.

Similarly, logistics partners have direct read-only access to the orders they will be delivering. This enables them to plan more efficiently and reduce wasted journeys.

“Giving customers direct access to their orders has helped transform customer confidence. They know they can rely on us to deliver on time, because they can see it for themselves.”

— SFCo CEO

6 Quality Management

There are numerous ways that a product could fail to conform to the client’s requirements. Mistakes or defects can occur at every stage, especially when manufacturing custom products.

Improving quality is a high priority for improving profitability. The costs of re-manufacturing or cancelling an order are high. Even if the product can be rectified, the additional time taken has a knock-on effect to the rest of the production schedule.

And of course, quality problems cause customer dissatisfaction. So, quality directly impacts profitability in the short-term and long-term.

Ideally any non-conformities are identified internally during quality assurance, but they may be reported by clients e.g. there was a misunderstanding, or the product was damaged during delivery.

| Sales team | Receive product defect claims from customers. |

|---|---|

| Quality team | Provide technical response to customer claims. Identify non-conformity before shipment to customer. |

| Production team | Investigate non-conformities, performing root-cause analysis. Implement corrective measures. |

Results

The new management team invested time and resources to improve every aspect of production quality. There is now a rigorous process to:

- Track every non-conformity whether identified internally or by the customer.

- Thoroughly investigate and identify the underlying root cause.

- Design and implement process changes to prevent issue recurring.

Quality has improved

- Fewer product defect claims by customers.

- Continual reductions in non-compliance.

- Cost of fixing defects has reduced.

- Quality management established as a culture within the firm.

“Quality is a company-wide team effort. Instead of apportioning blame, we are all working together to identify and remediate the root cause.”

— SFCo Quality Director

7 Manufacturing Transformed

The new approach has transformed how SFCo work and has established a positive platform for future improvements.

Employees and management are enjoying streamlined and organized processes. Instead of fire-fighting and chasing colleagues for information, they always have clear visibility.

Now many SFCo customers and suppliers have read-only access. Not only can they directly see production status at any time, but this level of transparency is a real boost to partnership and trust throughout the supply chain.

Next Steps

After the success of the first three processes, SFCo have started adding further processes for:

- Collaborative forecasting with customers for capacity planning.

- Document management for product documentation, procedures, contracts, and orders.

- Action plan to manage continuous improvement initiatives.

These new processes are initially being added to LiveDataset for internal use, and will be rolled out to customers and suppliers after they have bedded in.

LiveDataset is flexible. SFCo have successfully used LiveDataset to build themselves a range of business applications without coding. The processes are very specific to their business and enable people from each internal team, and customers, and suppliers all to work on their part of the same set of data.

The new SFCo management team have used LiveDataset to implement new processes that are transforming the business. Profitability is rising, and the company is planning to expand into new markets.